Snow removal is made quicker, faster, and more pleasant for the operator using Ariens thanks to the Auto-Turn steering technology in newer models of this brand. But what if this auto-turn technology begins to develop flaws and is no longer equal to the task? If this is the case, you should be aware of how to solve Ariens auto-turn problems.

This technology is only available on Ariens two-stage snow blowers such as the Deluxe 28 and Deluxe 30 models, as well as the Ariens Platinum Series, PRO Series, Hydro PRO Series, and Track Series.

Thus in this article, we will explore some of the issues that Arien snow blower auto turn may be giving you, as well as how to troubleshoot auto turn issues and solutions to the Ariens auto turning problems. So let us get into it.

Contents

Problems With Ariens Auto-Turn Snow Blowers?

Auto turns are a welcome addition to Arien’s new model snow blowers. Older versions of Ariens snow blowers have no auto-turning trigger steering.

An improved feature now has effortless control, no triggers, or precise lever turning. A smooth operation auto-turn™ steering technology throw snow easier, faster, and more comfortably.

However, sometimes there is trouble with auto-turn. Keep reading to learn more about auto-turn and what problems can occur with it.

How does Auto turn work?

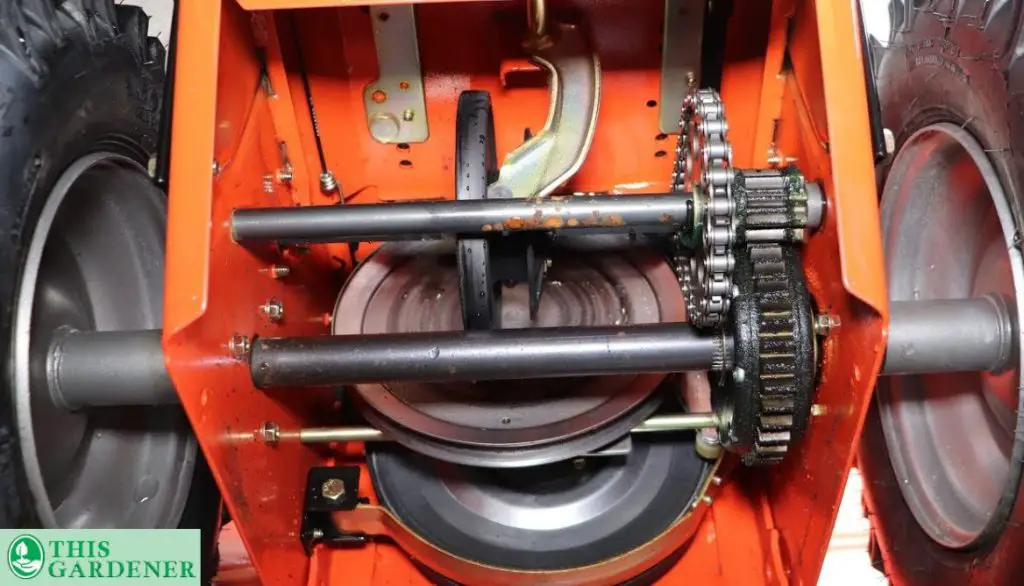

Auto-Turn by Arien’s new Snow blower has a differential that detects when you make a turn. The driving differential axle shafts rotate in the same direction as the snow blower when it moves forward.

When you commence a turn, the differential axle shafts are free to rotate in the direction you’re turning, but if the differential axle fails to meet these expectations, something is wrong. There are no severe issues with the new Ariens Auto-Turn differential.

So let’s look at the most often Ariens Auto-turn problems.

New and Inexperienced Owners

Ariens two-stage snow blower series exhibits inconsistent tracking or “pulling” to one side during operation when the auto turn is engaged. Then the tractor, or frame of the device, is usually out of a straight line with the auger housing, leading the snow blower Auto-TurnTM feature to detect movement and spin erratically.

You must be careful to handle your machine, and rather guide it than steer it. You should move the grips with your arms instead of your entire body, the Auto-Turn will operate much better.

Assembly and Set-up Issues

One thing you need to note when assembling your two-stage snow blowers is the handle and bolt tightening. Take care not to overtighten these bolts. It can break the plastic bushings and bend the black metal rod.

Read the manual attentively to avoid mistakes and ensure the gear oil is full after installation. More information on correct fuel and oil usage and maintenance can be found in your owner’s manual. When you’re done using the snow blower, ensure the drive and auger are deactivated. Turn off the ignition and slowly decrease the throttle down.

Housings are Not Seated on the Transmission Frame

If the transmission frame is not seated with the housings or if you ever need to change the driving belts, you should follow the steps below.

Step 1: Replace the new snow blower housing

To replace the new snow blower housing, set it on the rod and securely tip the tractor and blower together while holding the driving belt in the up position. To attach to a frame, use two cap screws.

Step 2: Tightening and adjust the screws

Tighten the screws while the handlebars are still in place. The engine shaving should be used to roll the attachment belt. While drawing the recoil starter rope, roll the belt under the belt finger. Check for at least 1/8 inch clearance around the whole finger belt (do it with an engaged attachment clutch). If required, make adjustments.

Step 3: Realignment of the attachment belt and sheave

Check the alignment of the attachment belt and sheave. If necessary, realign. Repeat with the blower sheave and brake pads, re-aligning as needed. If the belt slips, it must be adjusted. This can be done by changing the idler in the idler arm slot, which may increase belt tension.

Note: Slotted holes in the auger frame make it very easy to insert the mounting bolts while reassembling the snow blower.

Remember that the belt should clutch when the attachment clutch is disengaged. Replace the belt and crank parts, as well as the spark wire and the chute crank.

Other Items We Want to Highlight

There are others items associated with Ariens snow blower we want to highlight apart from the major ones, such as the Wheel Key, use of skid shoes, and inflated tires.

Missing Wheel Keys

Without the key that secures the wheel to the shaft, the wheel will spin freely. Only one axle has a retention ring. When it is not in use, the machine should move easily. If the machine is difficult to speed, something is incorrectly constructed or is binding.

You should hear the auto-turn system clicking when rolling and rotating the machine. To install these parts, place the machine in the service position; the wheels should turn readily. This is covered in the machine’s manual.

Skid Shoes Need to be Flat on Ground

Skid shoes are an effective way to increase the lifespan of your scraper blades. The skid shoes, the two steel plates attached to the snow blower housing exterior, can be adjusted to modify the clearing height of a two-stage snow blowers.

The height of the auger housing, which houses the augers and shaving plate, is controlled by the snow blower skid shoes. When set to the proper height, the skid shoe keeps the augers and shave plate from scraping against the paved surfaces.

Skid shoes degrade during snow blower operation, therefore, check the shave plate height frequently and adjust the skid shoes to be flat and closest to the ground to keep the shave plate 14 inches high.

Tire Inflation

A properly inflated tire will provide safe snow blowing, optimal traction and speed, good handling, and maximum tire life, underinflated tires might impair the performance of your snow blower.

To help the unit maintain grip and drive straight, pump the tyre to suitable, equal tire pressures. If the snow blower continues to turn in the same direction as the tire it is working on, ensure sure both tires are properly filled. The problem is exacerbated by the Auto-Turn, which “thinks” you want to turn in the direction with the least pressure.

Common Solutions for Ariens Snowblower Wheels, not Engaging

If the friction ring, v-belt, clutch cable, cogged belt, or traction control table has been tampered with or has difficulties, the wheel of an Ariens snow blower will not turn or engage. We’ll go over the difficulties and possible solutions for making the best use of your snow blower down below.

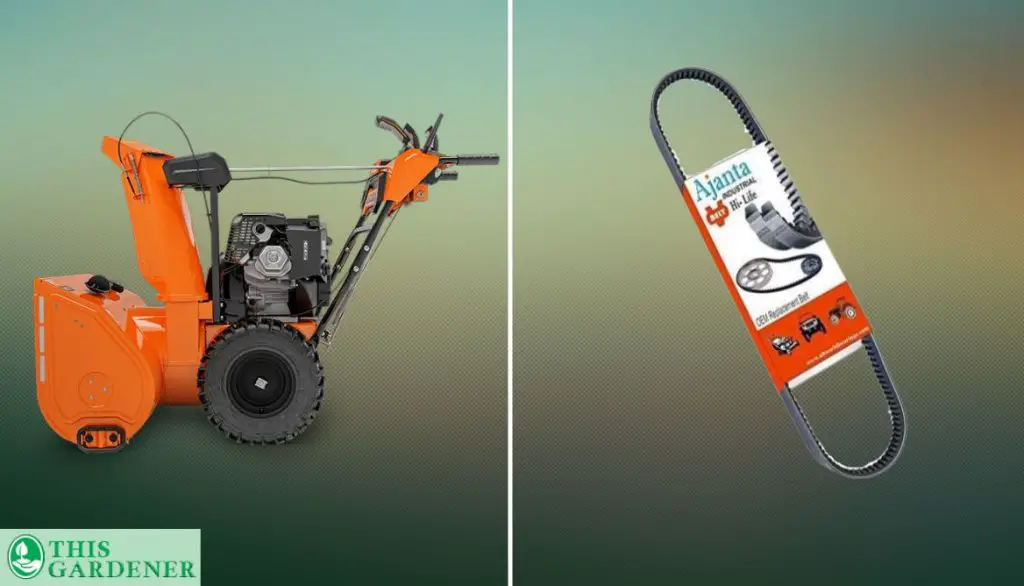

Ariens Snow blower V-Belt

The V-belt is the link between the engine and the transmission. The snowblower wheels will not turn if the V-belt is worn out, misaligned, or damaged. Examine the belt unit to see whether it is broken or worn out, and ensure it is properly adjusted. Replace the V-belt if it is broken or worn out.

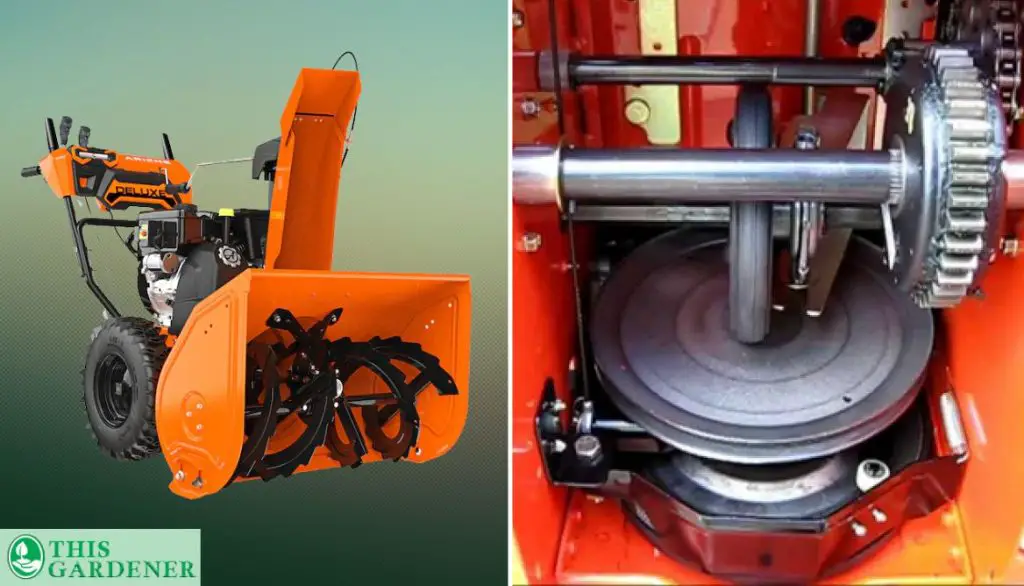

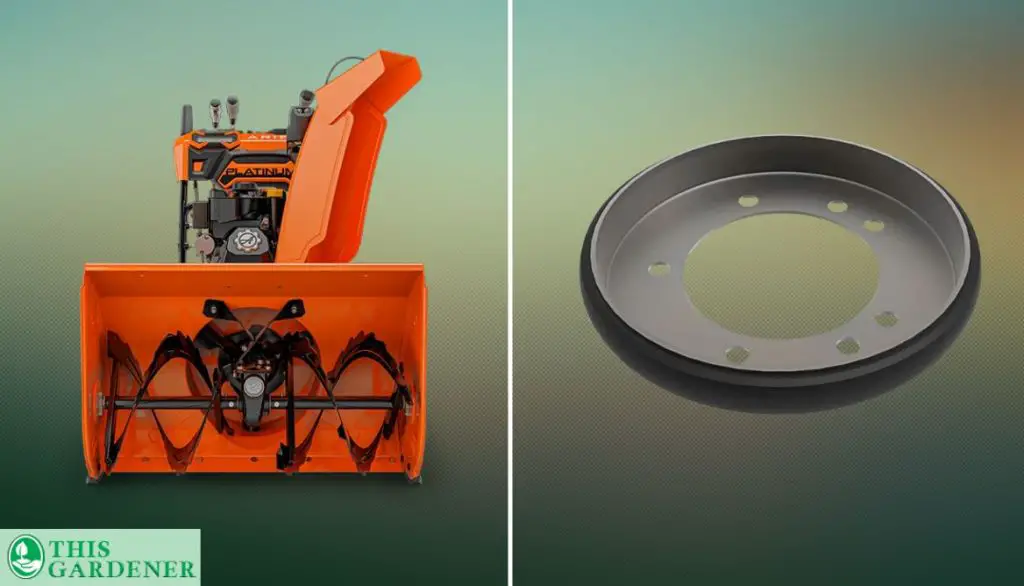

Ariens Snowblower Friction Ring

The snow blower wheels will not turn if the friction ring is worn out, oily, moist misaligned, or damaged. As a result, the drive plate and snow blower wheels will not engage. The friction ring (also known as the friction wheel) is made of rubber and has an outer layer that grips and turns the driving plate. If the friction ring is damp or greasy, clean it and the plate.

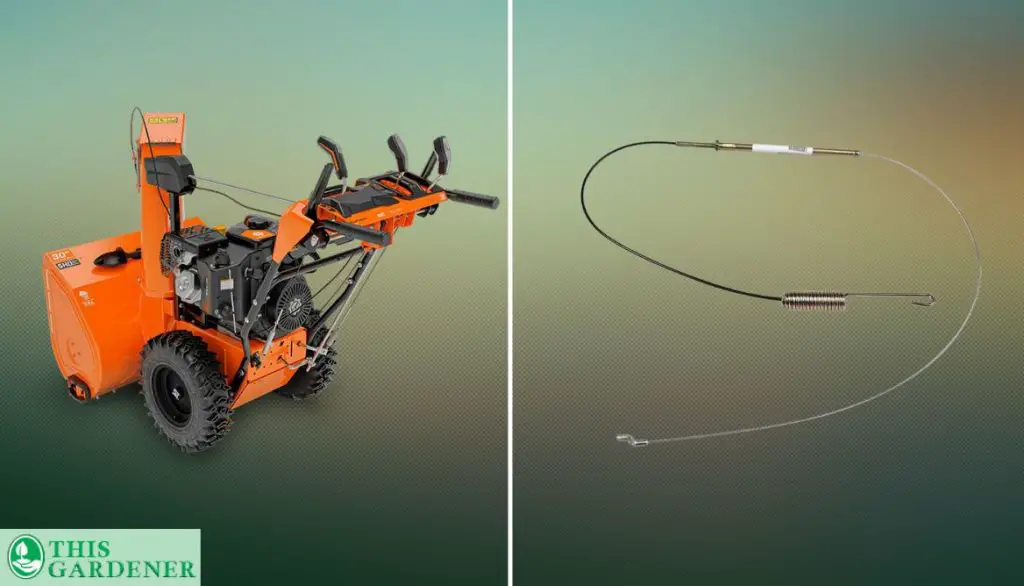

Ariens Snowblower Clutch Cable

Check the cable between the handle lever and the clutch assembly before using it. If the cable is broken or out of adjustment, replace it. Make sure the cable has the proper tension, and adjust the cable if necessary.

Ariens Snowblower Traction Control Cable

The traction control cable could be broken or incorrectly set. Examine the traction control cable to see if it moves easily. If the control cable does not move easily, lubricate it by squirting a small amount of oil into the end of the cable. Replace the traction control cable if lubricating it is ineffective.

Ariens Snowblower Cogged Belt

The cogged belt is the link between the engine and the transmission. The snowblower wheels will not turn if the cogged belt is worn out, incorrectly fitted, or broken. Examine the cogged belt to see whether it is broken or worn out, and ensure it is properly set. Replace the belt if it is broken or worn out.

FAQ

Does Ariens Auto turn work?

Yes, Ariens auto-turn works.

How do you adjust an Ariens Auto turn?

You can call for a local Ariens dealer toadjust for you or follow these steps:

– Loosening the skid shoe completely.

– Then loosen the two bolts on both sides of the machine.

– Confirm the scraper blade is square with the blower housing.

– Set the gap for the square blade.

– Use a 1/8 spacer to create a uniform gap.

– Tighten the skid shoe bolt.

What is Auto turn steering on Ariens snowblower?

The technology allows users to turn without adjusting speed, making snow removal easier, faster, and more comfortable.

Do all Ariens snowblowers have an Auto turn?

No, it is only available in the newer models of Ariens’ two-stage Snow Thro equipment.

How long do Ariens snow blowers last?

With proper care, snow plows can last about 20 years. The Ariens company also gives a three years warranty for home use and one year of warranty for commercial.

Conclusion

The auto-turn technology in Arien’s new model’s snow blower is a remarkable accomplishment because it contributes to the quality and speed of snow removal. However, the Ariens company needs to work on it more because it sometimes has troubles.

Have you ever encountered any problems with Ariens Auto turn steering? Please tell us in the comments box below.

- How to Get Potatoes to Sprout Eyes: Detailed Growing Guide with 3 Options - July 31, 2023

- Weight of a Medium Potato: Revealed in Detailed Guide - July 29, 2023

- Maris Piper Potatoes: 9 Substitutes You Should Know About - July 27, 2023

Hello! I’m Jessica Zander, a garden coach and consultant based in the Boston area (zone 6b), offering virtual consultations across the country and Canada.

I’ve been passionate about gardening since the early 1990s, and in 2022, I launched You Can Do It Gardening to empower individuals to feel more confident in their gardening endeavors.

Following a 30-year career in nonprofit finance and operations, I transitioned out of that field in mid-June of 2023 due to the growing demand for coaching services. Interestingly, my years of presenting financial statements to boards and finance committees proved to be valuable experience for teaching people about gardening! I enjoy sharing skills, providing guidance and suggestions, and collaborating efficiently with clients to make significant improvements to their outdoor spaces, both small and large. I also regularly teach at the Arlington Continuing Education and Cambridge Adult Education.

My approach is direct and practical, akin to Mary Poppins, but tailored to your garden. Clients find satisfaction in saving money and taking pride in their own gardening achievements.

Add comment